Shandong Xiangying New Materials Technology Co., Ltd.

Shandong Xiangying New Materials Technology Co., Ltd.

In today's competitive market, selecting the right manufacturer for UV Marble Sheet is crucial for ensuring product quality and meeting consumer demands. The global market for synthetic marble, which includes UV Marble Sheets, is projected to reach $1.25 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.5% from 2020 to 2025, according to a recent industry report by Allied Market Research. As designers and architects increasingly prefer materials that combine aesthetic appeal with durability, the demand for UV Marble Sheets continues to rise. Choosing a reputable manufacturer can not only guarantee superior product characteristics but also ensure compliance with environmental standards and technological advances. As we delve into the intricacies of this selection process, we'll explore key considerations that can help businesses thrive in this dynamic landscape.

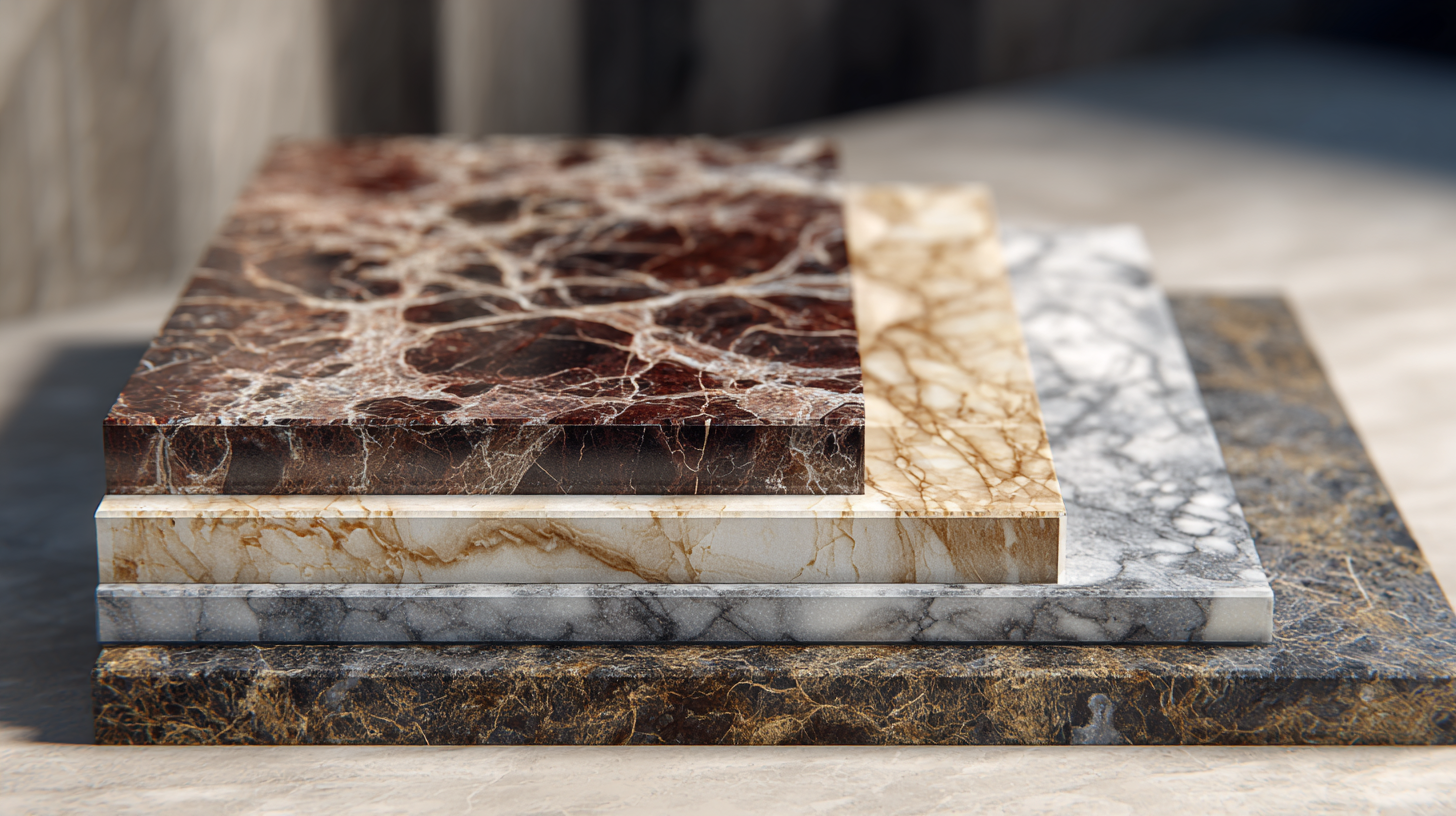

In today’s rapidly evolving market, UV marble sheets have emerged as a key player in the construction and interior design sectors. According to a 2022 industry report by MarketsandMarkets, the global UV marble sheet market is projected to grow at a CAGR of 7.5%, driven by the increasing demand for durable, aesthetically pleasing materials in residential and commercial applications. UV marble sheets offer superior resistance to scratches and UV rays, making them a preferred choice for various environments, including kitchens and bathrooms.

Moreover, the versatility of UV marble sheets caters to a range of design preferences. Industry experts highlight that these materials can imitate natural stone while being more lightweight and easier to install. Furthermore, a report by ResearchAndMarkets in 2023 noted that the rising trend of eco-friendly materials has influenced manufacturers to innovate and provide sustainable options. As a result, UV marble sheets have not only become a decorative choice but also an environmentally conscious one, positioning them as a critical component in modern design strategies.

When selecting a manufacturer for UV marble sheets, several key factors must be taken into account to ensure quality and reliability. First and foremost, consider the manufacturer's experience and reputation in the industry. A company with a proven track record is likely to produce superior products that meet industry standards. Researching customer reviews and testimonials can provide valuable insights into their reliability and product performance.

Another crucial factor is the availability of advanced technology and production techniques. Manufacturers investing in state-of-the-art equipment are better positioned to offer high-quality UV marble sheets with superior finishes and durability. Additionally, inquire about the sourcing of raw materials. Sustainable practices not only benefit the environment but can also enhance the quality of the final product.

Lastly, evaluate the manufacturer's customer service and support. A responsive and dedicated team can make a significant difference in the overall experience. Open communication channels are essential for addressing concerns or customization requests. By carefully considering these factors, you can make an informed choice and find a manufacturer that aligns with your needs and expectations.

When selecting a manufacturer for UV marble sheets, evaluating quality standards and certifications is crucial in a competitive market. A reliable manufacturer should adhere to international quality standards such as ISO 9001, which ensures consistent quality management processes. Certifications not only provide assurance of a company's commitment to quality but also signify that their products undergo rigorous testing and evaluation. This helps ensure that the UV marble sheets produced are durable, resistant to wear, and maintain their aesthetic appeal over time.

Additionally, manufacturers should ideally possess specific certifications related to their materials, such as GREENGUARD or similar eco-friendly certifications. These indicate a commitment to low emissions and safe manufacturing practices, making their products suitable for various applications, including residential and commercial use. By closely examining these quality standards and certifications, businesses can make informed decisions and select a manufacturer that not only meets their needs but also contributes to sustainability efforts in the industry.

When selecting a manufacturer for UV marble sheets, understanding competitive pricing and the value associated with your investment is essential. In a market saturated with options, it's crucial to assess how different manufacturers position their products in relation to price. A manufacturer that offers lower prices might seem appealing at first, but examining the quality of materials and the longevity of the product is equally important. Conducting thorough research on the reputation of potential manufacturers can help you strike a balance between affordability and durability.

Additionally, beyond mere pricing, it's vital to consider what value each manufacturer delivers. This includes factors such as customer service, warranty options, and the availability of customization. A slightly higher price point may be justified if it comes with superior service and customization features that cater to your specific needs. Ultimately, making an informed choice means comparing not just the costs but also the overall benefits provided by different manufacturers in the UV marble sheet market.

| Manufacturer | Product Type | Thickness (mm) | Price per Sheet ($) | Warranty (Years) | Customer Rating (out of 5) |

|---|---|---|---|---|---|

| Manufacturer A | UV Marble Sheet | 3 | 80 | 10 | 4.5 |

| Manufacturer B | UV Resistant Sheet | 4 | 90 | 8 | 4.7 |

| Manufacturer C | Premium UV Marble | 5 | 100 | 15 | 4.9 |

| Manufacturer D | Standard UV Sheet | 2 | 70 | 5 | 4.2 |

When selecting a manufacturer for UV marble sheets, accountability is crucial. Researching global manufacturers with proven tracks in similar industries can significantly influence your choice. For example, the pharmaceutical sector in India has established a strong reputation for research and innovation, contributing to its leadership on the global stage. According to recent industry analyses, investment in advanced technologies and manufacturing, particularly in regions like Melbourne, has propelled significant growth and innovation across various sectors. Firms that have demonstrated consistent delivery and quality, especially in industries that parallel your own, can offer valuable insights and benchmarks.

Tip: Always conduct a thorough background check on potential manufacturers. Look for established partnerships, quality certifications, and reviews from previous clients to gauge their reliability.

Furthermore, understanding the nuances of your chosen manufacturer’s operational framework is essential. The reliance on data analytics and artificial intelligence is reshaping efficiency in manufacturing, allowing companies to optimize processes and reduce costs. Implementing smart analytics can streamline production lines, ensuring adherence to quality standards while responding to market demands swiftly.

Tip: Consider manufacturers that integrate cutting-edge technology into their operations, as this can enhance product quality and consistency while reducing lead times.